Specialized Service

Linestop Procedures:

A. Hottap on the line is previously made, the linestop machine is attached to the temporary valve and the valve is opened. Linestop is hydraulically or mechanically pushed into line to plug the pipe. B. here are various types of line stopping heads. The type illustrated in the picture on the left can hold pressures ranging from 1000 psi. A single linestop can be used to temporarily stop and abandon a pipeline. C. Two or more linestops can be used in conjunction to isolate and bypass many intersecting lines at once. Fluid in the line is bypassed, leaving a workable dead section, in which, alterations, repairs, or valve additions can be achieved, while service provided by the line is continued. D. When the required work is completed, and the linestop is to be removed, completion machines are installed onto the temporary valves. An IFT completion plug is installed into the outlet flange of the linestop fitting. This allows the linestop machines and temporary valves to be removed. A blind flange is usually installed to finished the linestop operation.

Advanced Linestop Services

Pipeline linestops isolate a section of pipe, stopping its flow. IFT provides the most advanced line stop services available today! Sizes from 1/2" - 72" on any type of pipeline. Indoor line stops require various types of line stopping equipment and folding heads for tight inaccessible areas. IFT is the leader for indoor pipeline services. We can perform pipeline plug services on steam systems, air lines, chemical lines, chilled water systems & Prestressed Concrete cylinder pipe Line stop anywhere PCCP Line stop, any time. Changes to your manufacturing plant and piping systems can be solved without an outage. Pressures through 500 psi and temperatures through 500 deg. F. Get a quote for your indoor, outdoor, underground, or above, high pressure or hazardous pipeline linestop needs. Call IFT 1-800-221-3332

Cut Sheet PDF's

72" Linestop Thru 48" Tap

Linestop Services Slideshow

24” 90 degree elbow Linestop

Dual HDPE Pipe Linestop + Bypass Services

|

Job Status: Successful and Completed Job Date: February 7, 2014 PROJECT: Linestops and Bypassing HDPE Pipeline Click for a Short Cut to content using the links below Coupon Retention & IFT – T-46 Tapping Machine Hot tap "Coupon" Retention and Removal JCM - Generic Fitting Specification for HDPE Hottap & Linestop Linestop with Bypass – Photo / Inside Isolated Pipeline - Photo Description of Linestop™ Sequence Generic Specification HDPE – (DR-26) Linestop Removal of Temporary Valves Using Completion Flanges & Plugs International Flow incorporates multiple retaining wires to provide retention of coupon.The majority of our Hot tapping is performed vertically "on top" of the pipeline.Thus retaining the cut section or "coupon" is critical. Performing 24" Hottaps for retention safety requires a minimum of (4) sets of retaining wires to pass through the pipe section prior to the tapping cutter completing the tap. This safeguards the coupon from being lost into the system.

T-46 Tapping Machine 46" of travel performs 12" - 24" Taps ♦ Travel can be increased if desired to 60" with "T46-60 Rail and Boring-bar" ♦ Very Powerful Built in drive unit ♦ Tapping machine is hydraulic driven: 16 gallons at 2000 psi. is preferred. ♦ Machine has patented "Selectable-feed" ♦ 3" Boring Bar for ridged cutting. ♦ Gear driven for precision cutting and dependability ♦ Dual Hydraulic motor drive for non-stop cutting ♦ Mueller style cutters bolt up with use of an adapter ♦ 285 psi. working pressure with quoted adaptors. ♦ 285psi & 250 degrees (F) with provided packing. ♦ Higher Temperatures are available with optional packing. ♦ American std & British std, adaptors ♦ Operating max. pressure 285 psi. @ 100º F ♦ Operating temperature 250º @ 300º psi.

Cutting HDPE Is performed with sharp and fluted cutters. The pilot Drill performs the retention of the Cut section or "coupon" allowing it to be removed under pressure. JCM 452 Fabricated Linestop Sleeve – All Stainless Steel Gasket: Nitrile Butadiene Rubber (NBR, Buna-N) per ASTM D2000. Molded virgin rubber with a pressure activated hydromechanical design. Gasket is bonded into a cavity for internal and external retention. Gasket temperature range -40oF to 212oF (-40oC - 100oC) Gasket suitable for water, salt solutions, mild acids, bases, and sewage. Optional gasket materials available. Fitting Flange: Stainless steel, 18-8 Type 304. Bolts: Stainless steel, 18-8 Type 304. Blind Flange: Fusion epoxy coated Ductile Iron. Blind Flange: Fusion epoxy coated A-36 Ductile iron. Service Rating: 12" to 24" Outlets: 150 PSI. A Bypass is installed between the Linestopping machines.

HDPE PIpe is Generally smooth inside so many times Bubble tight Linestop Shudowns are common making it easy for the contractor to perform their work. LineSTOP® Specifications for HDPE Pipe (150 PSI OR LESS) Description of Procedure - The line stopping procedure is a means of temporarily plugging a pressurized pipe without disrupting pressure of service upstream of the line stop. A pressure tap is first made into the main, allowing insertion of the linestop device into the main under pressure. By using a special line stop fitting, the tapping valve can later be recovered after the plugging head has been removed from the main. NOTE: Because of expansion and retraction of HDPE it is suggested that mechanical connections be made using the following in mind. "If pipelines are on top of the ground and encounter more than a 10 degree temperatures fluctuations, you may see problems and may have to install a mechanical tee or fuse the connection". 1. Prior to ordering material: Excavate, dewater excavation, expose and clean the exterior of the main at the location of the linestop®. If main is heavily corroded; or if utilities will interfere with fittings, support/thrust blocking, or equipment; move location up or downstream to structurally sound pipe. a. On pipelines 14" and larger; it may be necessary to Caliper O.D. of mains to determine ovality. b. Verify wall thickness by stated SDR # or by hot tapping techniques and/or ultrasound methods. c. Backfill; restore as requested by Owner. 2. Re-excavate; dewater. Assemble Linestop® fitting(s) around the main. Install drain nozzle(s) and saddle(s) to then main. According to the HDPE manufactures information cutter size should be no larger than 90% of the pipe I.D. (Pipe O.D. ÷ SDR#= gives wall thickness x 2 walls=I.D.) 3. Pressure test per Engineer’s specifications. 4. Pour concrete support and thrust blocking. Allow curing per Engineer’s instructions. 5. Mount temporary tapping valve(s) to linestop® fitting(s). 6. Mount tapping machine; open valve; pressure tap; retract cutter with coupon; close temporary valve; remove tapping machine. 7. Mount International Flow Technologies, Inc. linestop® machine; open temporary valve; insert linestop® plugging head into main. a. If two or more linestops, insert downstream plugging headfirst. b. "Flow must be stopped momentarily while heads are inserted" 8. Test for shutdown at drain nozzle. 9. Cut downstream main. Install required fitting(s) and valve(s). 10. Equalize section of pipe through drain nozzle. 11. Remove linestop® equipment. 12. Install the completion machine; set completion plug; remove temporary valve(s); install blind flange(s). Drain Nozzles - Because some amount of leakage may pass linestops, a drain tap of 2" or greater shall be added to the line to determine the quality of the shut down. 1. Contractor shall have the option of recovering the drain valves by using linestop® type tapping nozzles with completion plugs, or abandoning the valves by leaving them attached to the nozzles. In either case, the outlet of each nozzle or valve shall be sealed with a blind flange, mechanical joint plug, or screwed pipe cap or plug. 2. The drain-tapping fitting shall consist of a saddle plate with a integral flanged nozzle to which a tapping valve can be attached in a pressure tight manner. a. The interior of the saddle plate, adjacent to and concentric with the O.D. of the nozzle, shall be grooved to retain a gasket, which shall seal the saddle plate to the exterior of the HDPE/DI main. This gasket shall constitute the only seal between the main and the fitting. b. Saddle shall be clamped to main by minimum of two "U" shaped stainless steel strap/stud assemblies of sufficient cross section to contain a line pressure of 200 psig. Extent of Shutdowns - The shutdown will be accomplished by using a linestop®. Because of possible, out-of-roundness in the main, "bottle-tight" shutdowns may not occur. A satisfactory shutdown is one, which allows the work to be accomplished (i.e. valve installation) using drainage pumps to dewater if needed. Preliminary Field Inspection of Mains - Dimensional, specification, and other data regarding the existing mains have been taken from pipe data. 1. Prior to ordering material, Owner shall excavate at each proposed location, take an O.D. reading and caliper the header diameter to determine ovality. a. If I.F.T. determines that data on pipe I.D. is not adequate I.F.T. may make one or more pressure taps on main to determine I.D. from coupons. b. Minimum size of test coupon shall be 1 7/8" diameter, drilled through a nominal 2" valve. Line Stop Fitting and Accessories - Fitting shall be a fabricated type split tee. It shall consist of two steel weldments; (1) an upper line stop flange saddle plate and (2) a lower saddle plate. These two saddle plates shall be continuous. 1. Line Stop Flange: The outlet of each fitting shall be machined from a 150 lb. Stainless steel plate (304). Flat faced and drilled per ANSI B16.5. Suitable independently operated locking devices shall be provided in the flange to secure the completion plug. 2. Line Stop Nozzle: The nozzle, which lies between the saddle and the flange, shall be fabricated from 304 stainless steel pipe. After welding and stress relief, the nozzle shall be accurately bored to accommodate the line stop plugging head. 3. Fasteners: All bolts, studs, and nuts used on line stop and drain equalization fittings shall be machined from Type 304 stainless steel. 4. Gaskets: Shall be molded form elastomer compounds that resist compression setting and are compatible with water in the 32 degree to 140 degree temperature range. Installation of Linestop® Fittings - Line stopping Contractor shall clean the exterior of the main to remove any debris, corrosion deposits, or other surface irregularities that might interfere with proper seating and sealing of each linestop® fitting against each main. Any structural defects in main, service connections, appurtenances, adjacent utilities, etc., that could interfere with the line stop installation shall be immediately reported to the owner. 1. Line stopping Contractor shall fit upper and lower saddle plate assemblies to main, thoroughly checking for proper fit to main. 2. Under no circumstances shall Contractor attempt to force, reshape or bend saddle plates by excessive tightening of saddle studs while linestop® fitting is assembled around the main. a. Any retrofitting shall be accomplished with the fitting removed from the main. Thrust Support and Blocking - Prior to mounting temporary tapping valve and pressure tapping machinery, Contractor shall install concrete thrust and support blocking specified by Engineer. Blocking shall reach a minimum cure strength specified by Engineer before any valves or machinery shall be mounted onto the linestop® fitting. Cutting Operation - Drilling equipment shall be in good condition and equipped with power drive to ensure smooth cutting, and to minimize shock and vibration. Cutting equipment shall be sharp and have a coupon retention device in the pilot drill suitable for retaining the size of coupon to be cut. REMOVAL OF IFT TEMPORARY LINESTOP® VALVES

Once the pipe modifications are completed, the temporary bypass and Linestop® machines are removed. IFT’s completion tool holds and installs a completion plug into the neck of the fitting to isolate the product from the temporary isolation valves. After installation of the completion plugs the temporary isolation valves are removed and the permanent blind flange is installed. Future reentry of Linestop machinery can be performed by reversing this procedure. IFT Completion Plug Assemblies

Completion plug assemblies come in many different styles (See Figure 1) IFT completion plugs for pressures through 300 psi. use a pin type flange. The inside threaded hole holds retainer pin which threads into the top groove of the completion plug. The outside thread is tapered to match a pipe plug that seals the pin assembly.

The completion plug fits into the flange and seals with an O-ring against the inside of the nozzle. The plug is held in place by the pin assembly that is installed from the outside with an allen wrench. (See Figure 3) Figure 1 Typical Completion Plug Assembly |

||

Wall / Tank / Concrete Vessel / Cylinder Tapping Services:

Tap Sizes: Our wall tapping assemblies are used for hot tapping onto concrete walls, concrete storage tanks, and large diameter concrete conduits, where a backing draw plate is impractical. We manufacture any size contour to match your needs, with any size outlet through 120", in 125, 150, and 300 lb. classes. The body is fabricated from carbon steel and is available in shop coat or fusion epoxy coat, with either shop coated, fusion epoxy lined, or mortar lined waterways. The assembly is fabricated to match the existing wall contour. Our stainless steel anchor bolts are used to attach the tapping outlet securely to the wall. For smooth walls, one Q-Ring seal is adequate, though for extra security two Q-Rings seals can be used. All assemblies include stainless steel anchor bolts, and a carbide drill bit structure for drilling the concrete structure. Any wall thickness can be tapped. 20' thick or thicker have been performed. Our patented Square Flange products allow: the Hot Tapping of Butterfly Valves and Plug valves; and can “leave no valve” after the connection. Get a quote for your indoor, outdoor, underground or above, wall tapping needs Call 1-800-221-3332

Up to 120" Wall Tapping Services

6" Walltap on a 12" concrete storage tank

Linestop.com Services

Hot Tapping Procedures For Concrete Walls and Tanks

In preparation of a wall tap, the surface on the existing wall should be pre- excavated, and inspected, prior to ordering the tapping anchor and seal plate. In most circumstances the wall surface should be flat and have no visible signs of cracking. If the surface is not smooth, or slight deformations exist on the wall surface, a diamond surface grinder can be used to smooth surface. Smooth grinding will improve the surface condition to ensure a gasket seal. If the wall has visible signs of cracking it is possible to seal the cracks, but choosing a different location may prove to be more practical. Once the connection point is inspected the anchor plate can be ordered. When ordering the anchor plate, please specify either, shop coating, fusion epoxy coating, or stainless and grade. Also indicate the type of anchor bolts, "low alloy" or "stainless steel." For installation to the wall, holes are provided through the anchor plate to allow the anchor bolt to be drilled into the wall with nuts that draw the anchor plate tight against the wall. Chemical adhesion of the anchor bolts is preferred by IFT. Once the bolts, anchor plate and nuts are installed, the gasket compresses against the wall surface to create a permanent seal. After the anchor plate installation is complete, the tapping valve shall be installed, and the valve bolts shall be tightened in a star alternate pattern, so the valve will mount flush. For valves 8" and larger, a permanent valve support is recommended. At this time the tapping machine will be installed and the anchor plate, tapping valve, and tapping machine will be pressure tested 25% over the working pressure, with a hydrostatic test-pump. Upon a successful test the tapping cutter of the hot tapping machine will be advanced forward and the wall will be hot tapped. Once the hot tap is complete, the shell cutter is retracted, and the tapping valve will be closed. At this time the tapping machine is removed and piping can be installed. Because of the cut-ability of most concrete, connections can be made at many angles into the wall. The connection can be made at an angle such as 45 degrees into the wall. This is considered an "angle tap". Also, very thick walls can be tapped by means of making several preliminary penetration cuts, removing the cutter and tapping machine, chipping away and cleaning out the area within the cut section, and reassembling the tapping machine to continue making the cut. (Repeating this procedure if needed). When the desired depth is achieved by the preliminary tapping, a final cut will be made to complete the live connection. .

Wall, Tank Vessel Concrete Cylinders Hot Tapping Services Slideshow

Industrial Pipe Leak Locating Services:

IFT provides freeze plug services on all industrial pipeline systems to locate small leaks nationwide. We specialize in natural gas, crude oil, and petroleum high-pressure pipeline systems. All pipelines are prepped by using a pipe inspection gauge or 'pig' to perform various maintenance operations on a pipeline system also known as 'pigging.' Water is then added to replace the fluid to help in the freezing and leak locating process. This is a plugging process IFT specializes in nationwide. Jeff Maichel, President of IFT, says "chasing a minute leak, that is only losing 1/10 of a pound every 20 minutes is a task our pipe freeze plug specialists are qualified to do here at IFT. We will work tirelessly day and night till the leak is located using our very own liquid nitrogen trucks to help expedite finding leaks." In the slideshow below IFT narrowed down a leak on a 12 mile stretch of crude oil to 600' of pipe. 300 feet of pipe was exposed and the leak was promptly located and repaired. A job well done using IFT's services.

Slideshow Video of Past Freeze Plugs

14" Stainless Steel Freeze Plug

Pipe Freeze Plugs for Hydrostatic Testing

Advanced Freeze Dog Leak Locating Services

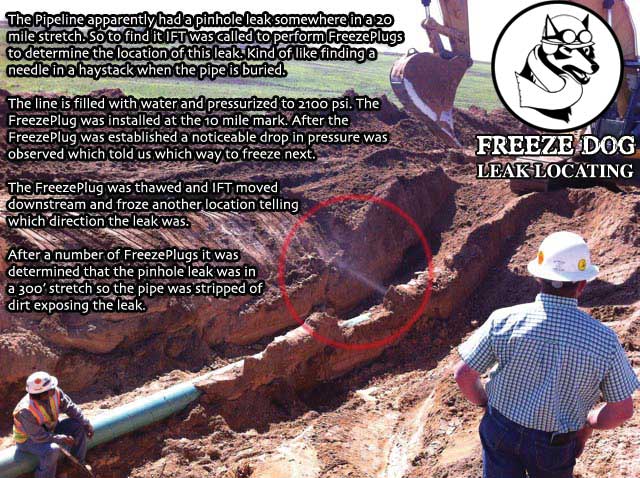

In this image: The pipeline apparently had a pinhole leak somewhere in the 20-mile stretch. So to fix the fix the problem, IFT was called to perform FreezePlugs to determine the location of this leak. Essentially, it is like finding a needle in a haystack when the pipe is buried.

The line was filled with water and pressurized to 2100 psi. The FreezePlug was installed at the 10-mile mark. After the FreezePlug was established a noticeable drop in pressure was observed which told us which way to freeze next. The FreezePlug was thawed and IFT moved downstream and froze another location telling which direction the leak was.

After a number of FreezePlugs, it was determined that the pinhole leak was in a 300’ stretch so the pipe was stripped of dirt exposing the leak.

Valve Installation and Replacement Services Slideshow

Pipe freezing can be performed on a variety of pipes, including:

Titanium

1/2" to 36" (13mm to 914.4mm) OD

CoCast & Ductile Ironated & Lined Pipe

Vertical, Horizontal, Inclined

Out of Round Carbon Steel

Stainless Steel

Aluminum

Lead

Copper

Brass

Cast Iron

Fiberglass

Transite

Internally / Externally Coated

Cement Lined / CMLC

Pipe freezing can be performed in most locations, including:

Malls & Shopping Centers

Fossil Fuel Power Plants

Nuclear Power Plants

Hotels & Apartment Complexes

Paper Mills

Hospital & Institutions

Industrial & Commercial Production Facilities

Telecommunications Industry

Water & Sewage Treatment

Office Buildings

Fire Protection Systems

Refineries

Schools

Chemical & Petrochemical Plants

Commercial Buildings

Hotels

Breweries

Ships

Isolation for Hydrostatic Testing

Leak Locating

Isolation for repairs or modification